How to make a working cell phone out of cardboard

For related resources, Design for Disassembly, Eco-Design, Environment and AD Technology guidelines related to this can be downloaded for free at:

MIT's David Mellis wants to help people unlock the mysteries of a cell phone.

“Making a cell phone seemed exciting but also challenging--which I thought would reveal more about the possibilities and limits of DIY practice,” he says.

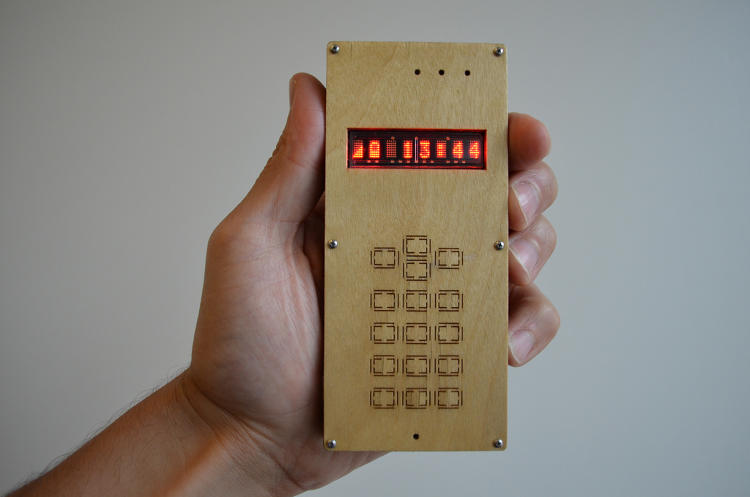

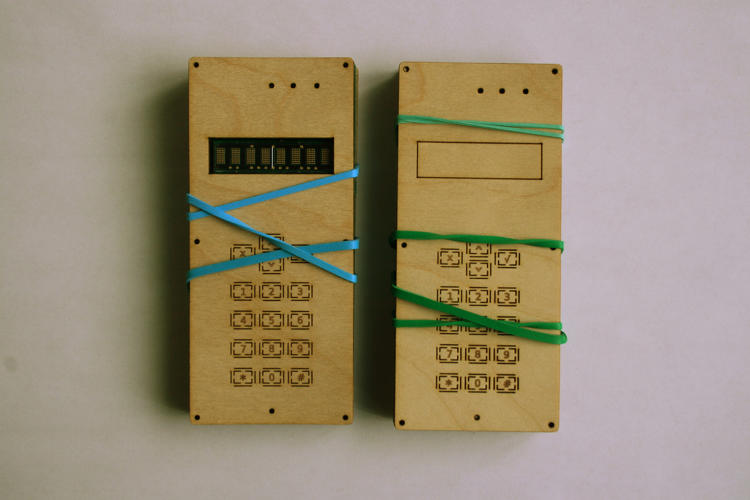

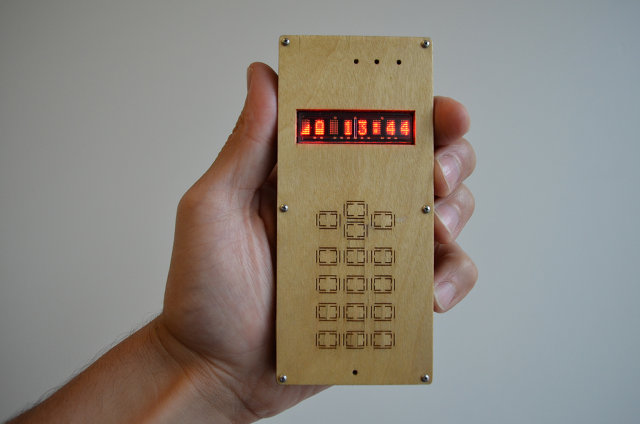

No one would confuse Mellis’s handiwork for Samsung’s or Apple’s. The dozen or so versions he’s built are not Internet-connected smartphones. Rather, they are feature phones, with simple black and white old-Nokia-style LCD screens or a red-on-black matrix LED.

But thanks to Mellis’s open-source designs, they’re "dumbphones" you can build yourself, from scratch, with about $200 of parts.

Mellis offers a method for making the enclosure that holds the electronics out of laser-cut plywood, though others have created their own from cardboard and 3-D printed plastic.

MIT's David Mellis wants to help people unlock the mysteries of a cell phone.

How To Make A Working Cell Phone Out Of Cardboard

With $200 in parts and some soldering skill, anyone can build what may be the world's first DIY cell phone.

There’s no device more simultaneously intimate and mysterious than the cell phone. It’s in your front pocket, carrying private texts and emails--and yet it’s also a voluntary tracking device and a technological black box. “There’s little DIY culture around them, at least in the west,” notes David Mellis, MIT professor and co-creator of Arduino, a popular DIY hardware platform.

But Mellis wants to change that.

“Making a cellp hone seemed exciting but also challenging--which I thought would reveal more about the possibilities and limits of DIY practice,” he says. Which is how he came to develop what may be the world’s first DIY cell phone.

No one would confuse Mellis’s handiwork for Samsung’s or Apple’s. The dozen or so versions he’s built are not Internet-connected smartphones. Rather, they are feature phones, with simple black and white old-Nokia-style LCD screens or a red-on-black matrix LED. But thanks to Mellis’s open-source designs, they’re "dumbphones" you can build yourself, from scratch, with about $200 in parts. Mellis offers a method for making the enclosure that holds the electronics out of laser-cut plywood, though others have created their own from cardboard and 3-D-printed plastic.

The process is not exactly papier mâché. You have to solder 60 components, many of them tiny, some of them hazardous. ("Be careful of the polarity on the large (1000 uF) capacitors," his directions note. "They may explode if you solder them backwards.") But Mellis says a half dozen or so have emailed him the results of their labor, in addition to those who’ve built them at workshops at MIT and in Sweden.

“Some are interested in learning more about how devices work; others just need a new phone,” says Mellis. “Some wanted to explore different design possibilities; others were more interested in DIY as an alternative to buying devices from big companies. Some people have just been looking for a fun, geeky way to spend a weekend.”

Mellis himself has been using a DIY phone as his primary phone for over a year. “The current one has been going strong for about five months so far,” he says.

Original post: